The meticulously designed Zebra ZT410 printer is durable and delivers exceptional performance in a wide range of applications. This series of printers ensures your critical business operates efficiently. Built on the Z series’ field-proven reliability, the ZT410 enhances print speed, print quality, and connectivity options.

The ZT410 printer is exceptionally easy to use, featuring an intuitive icon-based LCD graphical user interface and easy-to-install supplies. Furthermore, the ZT410 printer includes standard USB, serial, Ethernet, and Bluetooth connectivity. Expanded RFID capabilities provide enhanced tracking, deeper visibility, and business insights.

The ZT410 is a 4-inch model that comes standard with a range of advanced features to ensure your printer investment meets your needs now and in the future. Its all-metal frame and unique folding door design make it ideal for use in space-constrained environments. With Zebra’s Link-OS environment—an innovative operating system that combines a powerful multi-platform software development kit (SDK) with software applications—the ZT410 printer can be easily integrated, managed, and maintained from anywhere in the world.

Zebra ZT410 Product Advantages:

◆ Application Flexibility

* Extend your printer’s performance with a wide range of excellent media features and media delivery options.

* Customize your printer to match current and future business needs with media handling options available to the end user.

* Standard serial, USB, Ethernet, and Bluetooth capabilities—along with two open media slots—enable you to utilize non-standard connectivity options.

* Extended RFID functionality is easy to install and use.

* High-resolution printing ensures excellent output quality for small label applications.

◆ Easy Integration

* The USB host port allows for easy data transfer from USB flash drives via mapping and extended mapped drive memory, simplifying printer configuration.

* In addition to ZPL and EPL, the Virtual Device application enables Link-OS-enabled printers to support some common existing printer languages and competitor printer languages—effectively ensuring your return on investment.

◆ Ease of Use

* Dynamic QR codes provide web-based on-demand support for quickly resolving printer errors.

* With Print Touch, these Link-OS-enabled printers offer web-based startup using Near Field Communication (NFC), providing easy access to Zebra’s comprehensive knowledge base, including instructional videos and product support.

* Illuminated media and ribbon paths allow for easy viewing of the printer’s internals, even in low-light conditions.

◆ Easy Management

* Zebra’s Link-OS environment offers enhanced functionality for monitoring, managing, and maintaining printers from anywhere.

* Cloud connectivity enables Link-OS-enabled printers to securely interact directly with the cloud environment for printing and device management.

Profile Manager allows you to edit and manage a single printer, volume printer, or all Link-OS-enabled printers on your network from anywhere in the world.

◆ Applicable Scenarios

* Manufacturing – Work-in-Process Management – Product ID/Serial Number – Packaging Labels – Receiving/Handling Labels

* Transportation & Logistics – Order Sorting/Packaging – Shipping/Receiving – Direct Packaging – Compliance Label Printing

* Retail – Distribution Centers – Store Back-Office Operations

* Healthcare – Laboratory Labels – Blood Bank Labels – Asset Tracking – Drug Label Printing

Zebra ZT410 Detailed Specifications

Standard Features

● Printing Method: Thermal or Thermal Transfer

● Printing Mode: Thermal Transfer and Thermal Printing

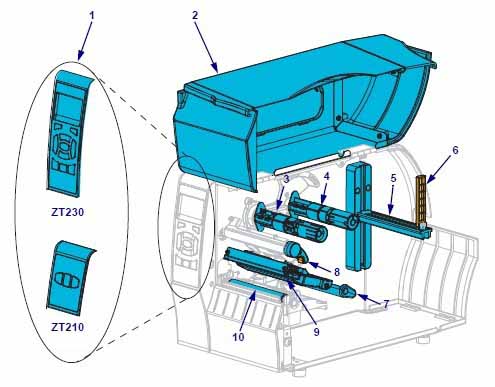

● Design: Metal frame and folding metal media cover with a large, clear window

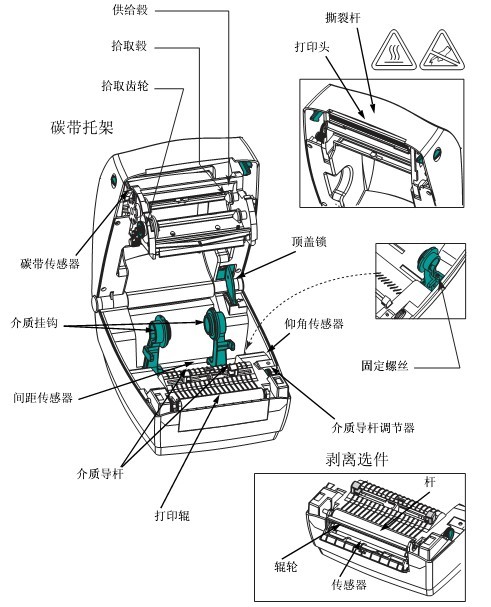

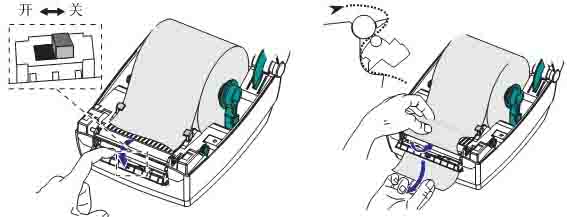

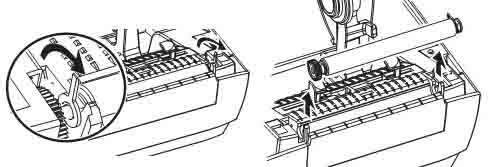

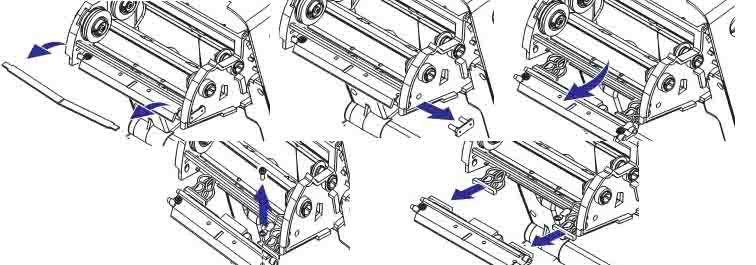

● Side-mounted consumable loading for simplified media and ribbon installation

● Excellent print quality with Element Energy Equalizer (E3) technology

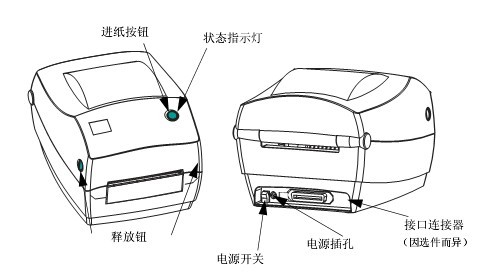

● Communication: USB 2.0, High Speed, RS-232 Serial, 10/100 Ethernet, Bluetooth 2.1, USB host port

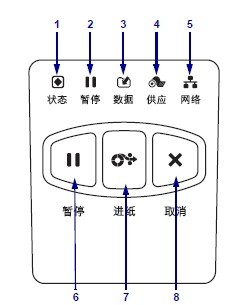

● Backlit, multi-graphic LCD display with intuitive menus and an easy-to-use keyboard for quick operation

● Dual-color status LEDs for quick monitoring of printer status

● ENERGY STAR certified

Print Specifications

● Resolution: 203dpi (8 dots/mm), 300dpi (12 dots/mm) (optional), 600dpi (24 dots/mm) (optional)

● Memory: Standard: 256MB RAM, 512MB Flash

● Maximum Print Width: 4.09 inches/104 mm

● Maximum Print Length: 203dpi: 3988 mm; 300dpi: 1854 mm; 600dpi: 991 mm

● Maximum Print Speed: 14 inches/second (356 mm/second)

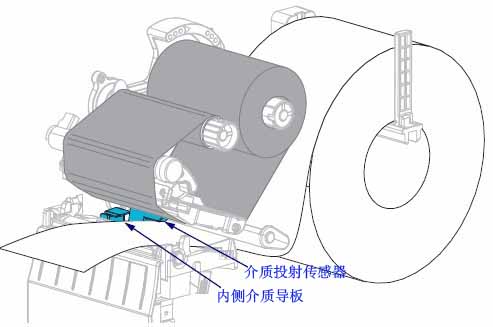

● Media Sensor: Transmissive and Reflective

Media Characteristics

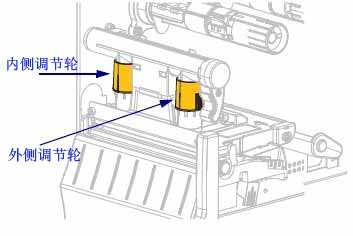

● Media Width (Label and Backing): 1 inch/25.4 mm to 4.5 inch/114 mm, tear/cutter; 1 inch/25.4 mm to 4.25 inch/108 mm, peel/rewind

● Maximum Length of Non-Continuous Labels: 39 inch/991 mm

● Maximum Media Roll Size: 8 inch/203 mm, Core Outer Diameter 3 inch/76 mm, Core Inner Diameter

● Media Thickness: 0.0023 inch/0.058 mm to 0.010 inch/0.25 mm

● Media Types: Continuous paper, die-cut paper, notched paper, black label paper

Ribbon Characteristics

● Maximum Outer Diameter: 450 meters: 3.2 inches/81.3 mm, Core Outer Diameter: 1 inch/25.4 mm, Core Inner Diameter

● Standard Length: 1476′/450 meters

● Width: 2.00 inches/51 mm to 4.33 inches/110 mm

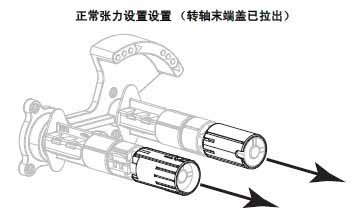

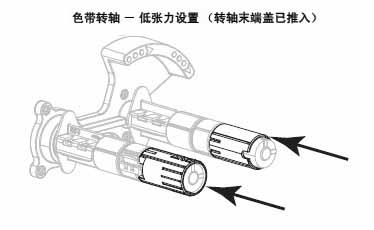

● Ribbon Setup: Ink side of the ribbon is wound outwards; optional ribbon reels can be used for ink side winding inwards.

Operating Parameters

● Operating Temperature: 40°F/5°C – 105°F/41°C

● Storage/Transportation Ambient Temperature: -40°F/-40°C – 140°F/60°C

● Operating Humidity: 20-85%, non-condensing

● Storage Humidity: 5-85%, non-condensing

Electrical Parameters

● Automatic detection (PFC compliant) 100-240VAC, 50-60Hz, rated power 100 watts

● ENERGY STAR certified

Physical parameters (closed state)

● Width: 10.6 inches / 269 mm

● Height: 12.75 inches / 324 mm

● Depth: 19.50 inches / 495 mm

● Weight: 36 lbs / 16.33 kg

Fonts/Graphics/Symbols

● 16 built-in scalable ZPL II bitmap fonts and two built-in scalable ZPL fonts

● Scalable smooth bitmap fonts for Asian and other international languages

● Unicode: suitable for multilingual printing

● Downloadable objects include images, scalable fonts and bitmap fonts, label templates and formatting.

● The IBM Code Page 850 international character set is available for fonts A, B, C, D, E, F, G and 0 via software control.

● Code Page 1250, 1252, 1253, 1254, and 1255 support font 0.

Barcode Types:

● 1D Barcodes: Code 11, Code 39, Code 93, Code 128 with A/B/C subsets and UCC Case Codes, ISBT-128, UPC-A, UPC-E, EAN-8, EAN-13, UPC and EAN 2- or 5-digit extensions, Plessey, Postnet, Standard 2-of-5, Industrial 2-of-5, Interleaved 2-of-5, Logmars, MSI, Codabar and Planet Code

● 2D Barcodes: Codablock, PDF417, Code 49, Data Matrix, MaxiCode, QR Code, TLC 39, MicroPDF RSS-14 (and additional codes), Aztec

Link-OS Solutions

: ● Documentation Design: Quickly design custom printing solutions using business data and Zebra’s intuitive plug-and-play design tools.

● Device Integration: Zebra’s applications and products help you integrate Zebra devices into existing systems.

● Device Management: Manage local and global printing operations with Zebra’s device management tool suite.

● Developer Tools: Provides the tools you need to create your own applications, including documentation, source code, programming languages, templates, and more.

Firmware

● Built-in ZPL, ZPL II, and EPL programming languages can be selected via software or front panel.

● Supports XML printing – Enables XML communication for barcode label printing.

Options and Accessories

● Communication

* Parallel Port (Bidirectional Interface)

* Wireless: ZebraNet Print Server — Supports 802.11a/b/g/n networks via internal integrated options supporting Webview and Alert functionality

● Media Handling

* Rewinder: Rewinds all printed labels inwards onto the 3-inch core, and can also peel and rewind backing paper (factory setting only)

* Peeler: Forward backing paper, passively peelable

* Peeler: Backing paper take-up option — When used with the peeler option, the entire backing paper take-up shaft can accommodate various standard printers

* Cutter: Forward-facing guillotine cutter and receiving tray

* 1-inch core inner diameter media supply rack

* Ribbon supply shaft supports ribbon ink-side inward winding

● Radio Frequency Identification (RFID)

* Supports signage compatible with UHF EPC Gen 2 V1.2/ISO 18000-6C

* Integrated RFID system can be upgraded by the user in the field

* Adaptive coding technology automatically selects the optimal coding settings

● Keyboard Display Unit: Supports KDU Plus and ZKDU – Input variable data, retrieve stored format, suitable for standalone applications.